Chillers

The water cooled platen chiller is a very useful gizmo. You just about need one if you’re grinding with a belt warped around a formed platen, but even folks doing regular flat grinding have found these to be very useful. I’ve gotten a lot of great feedback about these and I use mine all the time and wouldn’t want to be without it. Grinding against a cool platen is a good thing.

These have an internal meandering water path circuit where you can pump, siphon or otherwise flow water to control the temperature of your platen. I use ice water and get mine cold.

The mating surface is precision machined flat and the back of my steel platens are also precision machined flat so you can simply bolt these up and get fairly decent heat transfer. For better heat transfer or to use a platen I didn’t manufacture you can use a little thermal grease during assembly to get really good heat transfer.

The chiller is sealed with a buna N o-ring that is rated to 250 F. The o-ring is compatible with water, antifreeze and most oils. It is not particularly compatible with acetone, so if you’re planning to flow subzero acetone through it for use as frozen quench plates – you probably shouldn’t. The assembly can be opened to remove clogs or replace the o-ring if necessary. If opened, you should use a little smear of grease to lubricate the o-ring upon reassembly.

The pipe thread is a standard 1/4 NPT. You are responsible for hooking up your own coolant supply. I recommend swivel push-to-connect fittings and 1/4″ or 3/8″ plastic tubing, though rubber hose and hose barbs work too. I’m using a dinky little centrifugal pump here and a bucket of water. The meandering coolant path in the platen chiller induces a lot of turbulence in the water flow which helps you get good heat extraction without needing a lot of water flow. An aquarium pump is adequate. Or you might opt to hook up to your regular water supply and simply dump the water (though you’ll go to hell for wasting water). Just remember you don’t need huge flow or pressure here. Keep up with your tubing to keep it out of the grinder wheels and mechanism using zip ties or similar.

Put ice in your bucket for a cold platen. This can reduce your need to lift while grinding, particularly when using formed platens that can get extremely hot.

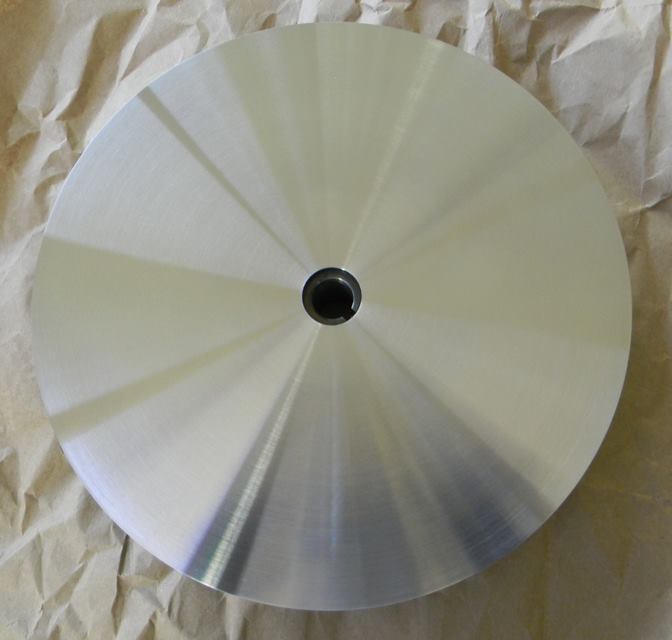

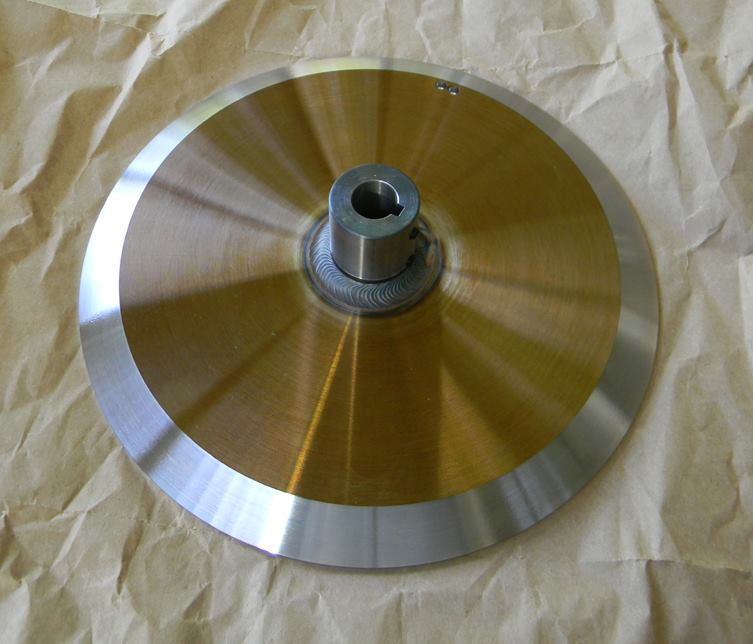

Disks

These are 9″ grinding disks made of hardened alloy steel (4130 HRC 44), turned in a way to minimized runout and then balanced. They were made by request in response for a need for industrial quality grinding disks made for professional use.

These disks are currently out of production.

Radius Platens

Radius platens simulate large wheels. They’re called a “radius platen” because they’re machined with a radius. The size number references the size wheel they simulate. So a 36″ radius platen actually has an 18″ radius. It simulates a 36″ diameter wheel. These are made of A2 and hardened to HRC63-64. There are three sizes that simulate large wheels, 36″, 48″ and 72″.

Flat Platens

We also have flat platens with end radius, large and small. They’re made of 1/2″ A2 hardened to HRC 63-64. “Small” has an end radius of 1/8″ on one end and 1/4″ on the other end. “Large” has an end radius of 1/4″ on one end and 1/2″ on the other end. These can be used for lengthwise grinding with the top wheel removed. The mounting holes are blind to prevent a witness mark from showing in your work.